EFI

Performance Fuel Systems "101"

This is a summarized but complete overview of the proper way to

plumb a Mercury Racing EFI outboard powered boat.

Production EFI’s and ProMax series motors can benefit

from these guidelines however they will not need the same

size fittings, hoses or fuel pumps. These designs use vacuum

pumps to feed a self-contained system therefore the plumbing

is not as demanding. The majority of Performance Outboards

are crankcase injected Mercurys. Therefore, they are the

target of this topic.

We must start off by noting that this discussion applies to race boats, as

certain practices do not always agree with USCG/marine survey/ insurance

industry regulations. For example, the anti-siphon valve that no doubt came

with your new boat, does not go well with that new drag motor you are about

to install. The ultimate fuel system does not use stand pipes or shut-off

valves, but rather fittings in the bottom of the tank. The good news is that

outboard regulations are less addressed than their inboard counterparts.

Engines, exhaust manifolds, belts, pulleys, alternators all in the enclosed

bilge demand more attention than an outboard or two hanging off the transom.

The most common rigs do utilize stand pipes in their tanks, which can easily

be designed to work efficiently.

Perhaps, after some people finish reading this article, they may say “I

don’t have it like that” or “never had a problem so why

change it?” That may be so, but the beauty here is that the correct

method is very inexpensive and the owner can easily do it themselves. When

you do have an engine failure or are not running as quick or as fast as your

buddy with a similar rig, it is nice to be able to rule out improper fuel

delivery as the culprit.

We will not drag out fluid

dynamics calculations that take into account internal hose friction,

temperatures, or viscosity. That would be boring and unnecessary.

This article comes from 28 years in the racing business both with

cars and boats. Hardly a week goes by that we are not on the telephone

explaining these principles that we are about to cover.

OK, now for the fun stuff.

One single sentence sums

up this entire article.

“ Do not starve the suction

side of the High Pressure pump”

Starvation is commonly achieved in

many ways:

Small Hose

( we have seen people stretch

-6 hose over a -8 barb)

Small Fittings

(

Easily, the most common condition is the correct hose size coupled

to a fitting with too small an inside dimension)

Collapsed and Kinked Hose

(We serviced a 30’ offshore

cat with unmounted sponson bladders that worked the hoses to the

point of internal breakdown)

Stand Pipes - Too

Short, Cracked or Even Too Long

(plastic ones jammed to the bottom

of the tank always raise an eyebrow)

Horribly Restrictive Screens at the Stand Pipe Entry

(a sometime necessary

evil on boats with deteriorating built-in fiberglass tanks).

Most Often

the Biggest Problem Starts at the Very Beginning

(The “Hard” 90

degree fitting at the top of the tank’s stand pipe with the

infamous anti-siphon check valve barb may be lurking in your boat

at this very moment)

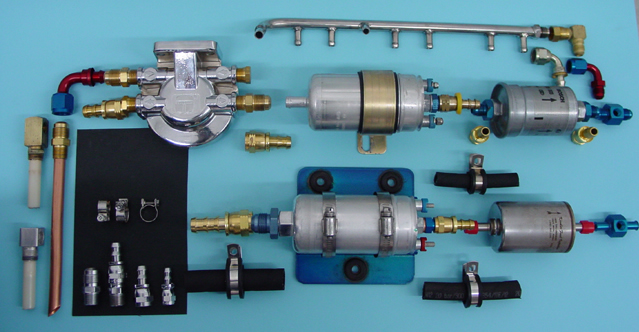

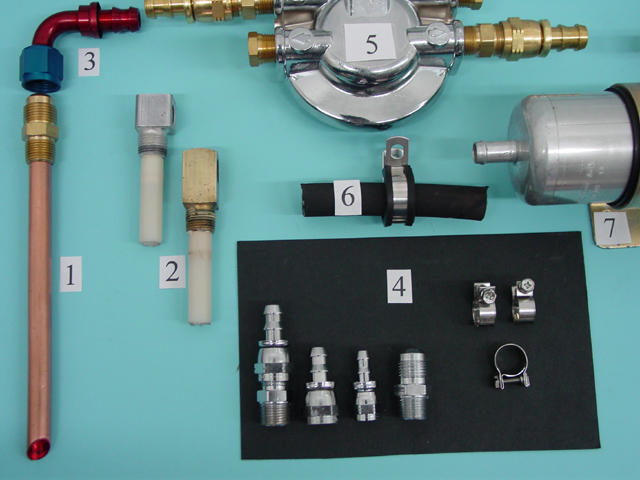

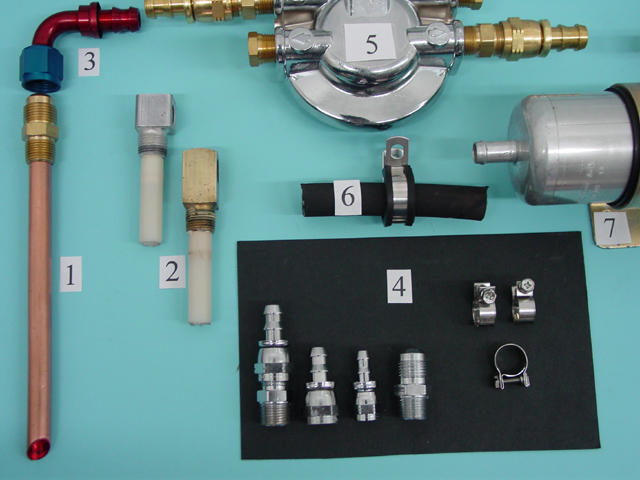

Figure

1 shows one simple way

of making a stand pipe for your existing tank. We use ½” o.d.

soft copper tubing (the kind that is sold in coils). Tanks usually

have a 3/8” pipe female threaded bung or bushing on the top,

so simply machine a brass 3/8” pipe male to -8 adapter so that

the straightened ½” o.d. copper tube slides inside.

Solder them together with silver solder (lead solder works fine as

well) and you are now well on your way to success.

Figure

1 shows one simple way

of making a stand pipe for your existing tank. We use ½” o.d.

soft copper tubing (the kind that is sold in coils). Tanks usually

have a 3/8” pipe female threaded bung or bushing on the top,

so simply machine a brass 3/8” pipe male to -8 adapter so that

the straightened ½” o.d. copper tube slides inside.

Solder them together with silver solder (lead solder works fine as

well) and you are now well on your way to success.

Figure

2 are examples of what you do not

want. These are however widely used and tolerable in another system’s design that

use transfer pumps to fill a “catch” tank. We will

discuss this later in the article.

Figure

2 are examples of what you do not

want. These are however widely used and tolerable in another system’s design that

use transfer pumps to fill a “catch” tank. We will

discuss this later in the article.

Figure

3 Top off the new -8 adapter with a TUBE 90 degree elbow. Do

not use any more 90 degree fittings en route to the high pressure pump

inlet (suction side of system).

Figure

3 Top off the new -8 adapter with a TUBE 90 degree elbow. Do

not use any more 90 degree fittings en route to the high pressure pump

inlet (suction side of system).

Figure 4 shows some samples of fittings that we had chromed. Fittings

are available

in a variety of metals and platings. Tube 90 degree elbows made in brass unfortunately,

do not seem to be available.

available

in a variety of metals and platings. Tube 90 degree elbows made in brass unfortunately,

do not seem to be available.

When you use brass fittings in salt water applications (which is correct) spray

them with a light coat of clear “krylon” to stall the inevitable

green discoloration. Pick and choose the fitting alloy that suits you. In most

of the rigs that we are concerned with in this discussion, electrolysis from

dissimilar metals will not cause a problem. It certainly would on larger center

console outboard boats left in marinas overnight. Shore power hook ups and

many electrical devices on board would make bonding and zincs mandatory. A

side note worth mentioning is to avoid the temptation to use stainless braided

hose assemblies especially in salt water applications. They may be necessary

in your blown 46’ Skater, street rod, or race car, but stay away from

then in your outboard hot rod. The following are two examples of why you should

not use them.

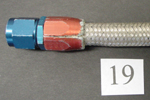

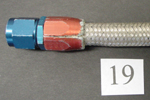

Figure

19 demonstrates electrolysis formed under the hose end

at the stainless steel braid. This hose assembly was removed

from the bilge of an outboard offshore race boat that was craned

out every afternoon. It never sat overnight in a marina. Stainless

steel and aluminum together may be the the best recipe for

electrolysis. Stainless braided hoses are risky in another

respect. In a thrash a steel fuel hose assembly accidentally

draped across a battery will no doubt spoil the weekend. Some

shops use plastic coated braided -4 trim hoses for this reason.

(they do turn ugly amber color however).

Figure

19 demonstrates electrolysis formed under the hose end

at the stainless steel braid. This hose assembly was removed

from the bilge of an outboard offshore race boat that was craned

out every afternoon. It never sat overnight in a marina. Stainless

steel and aluminum together may be the the best recipe for

electrolysis. Stainless braided hoses are risky in another

respect. In a thrash a steel fuel hose assembly accidentally

draped across a battery will no doubt spoil the weekend. Some

shops use plastic coated braided -4 trim hoses for this reason.

(they do turn ugly amber color however).

Figure 4 Also shows a few stainless

steel band clamps which are a tasteful choice over ugly, hose

wrecking worm clamps. These clamps are available in all necessary

sizes.

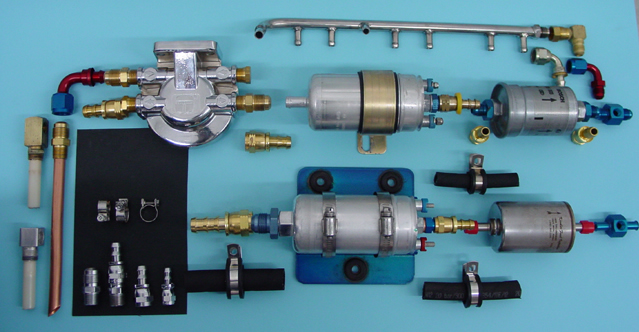

Figure 5 shows the sometime optional water/filter

base. We say optional because drag race and even river race boats (single engine)

consume most of their small tank’s volume on a daily outing. If you choose

not to use the water separator, be sure to fill the tank using a “race

car” funnel

with an internal bronze screen which removes water before it contaminates the

tank. Add a commercial coffee filter into the funnel to trap debris. This filter/funnel

set up will be easier to use if you install an “aero” style cap

onto the top of the tank. We prefer this method in lieu of a water separator

filter in the small EFI powered hot rod boat.

Larger hulls with big or multiple tanks, require water separator filters in

their system. Gasoline sitting in hulls for a time will collect moisture and

fueling in marinas may pose a problem.

Years ago, Mercury Racing generated a service bulletin for the ProMax series

motors prohibiting the use of hull mounted water separators. Mercury must have

had warrantee issues due to inadequate fuel system rigging, citing that their

powerhead mounted water separator was adequate; which it was. The problem arises

in the real world. The following is one example. You are returning from a weekend

of fishing and diving in your triple ProMax powered center console from Bimini

(Bahamas) to Miami. Halfway across in five to seven foot gulf stream seas,

your motors feel the ill effects of the bad load of fuel that you recently

bought. The only fix is to constantly dump the water separators that are not

safely mounted inside the bilge. Changing the motor mounted filter on the center

engine is an annoying process inside the shop, never mind hanging over the

transom while waves crash over you! The point of this story is that by properly

plumbing any boat’s fuel system, you can enjoy unexpected benefits that

may arise. When installed properly, all ProMaxes can safely run hull mounted

water separators without a problem.

Back to Figure 5 We

use a large style 3/8” pipe

water separator base. The large  3/8” pipe

openings (as opposed to Merc’s ¼” pipe one) allow us to

easily ream the inside passages to .400” to improve flow. Blending the

inside corners adds a nice detail as well. If you choose to install

a water separator filter in your rig, this is the one to use.

3/8” pipe

openings (as opposed to Merc’s ¼” pipe one) allow us to

easily ream the inside passages to .400” to improve flow. Blending the

inside corners adds a nice detail as well. If you choose to install

a water separator filter in your rig, this is the one to use.

Figure 6 is a sample of -8 Push-loc

hose with a stainless steel Adel or cushion clamp. The -8 hose

is used for the inlet side of the two most common Bosch fuel

pumps. Be sure to double clamp this connection.

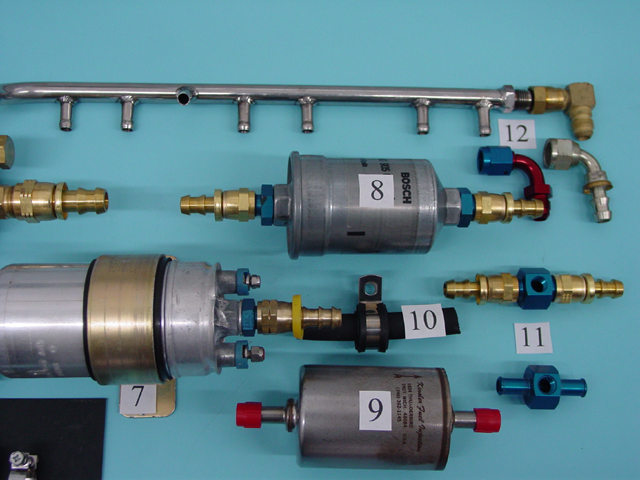

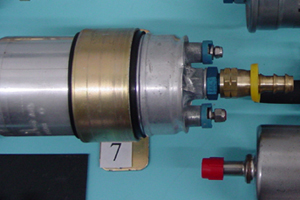

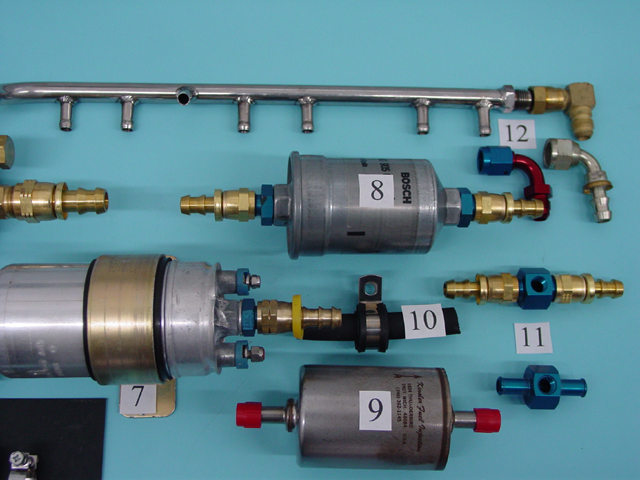

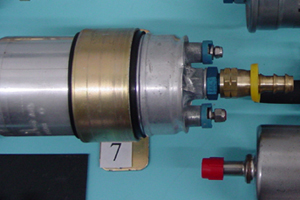

Figure 7 Shows

a Bosch High Pressure fuel pump. These pumps were original equipment

on Mercury Racing’s 260 and 280 H.P. motors. They can be

installed vertically and horizontally. It is important to mount

these pumps low in the hull. ( bottom of fuel tank is optimum)

These pumps have extremely tight internal clearances that require

clean gasoline. A vast majority of these pump’s failures

are caused by dirty fuel.

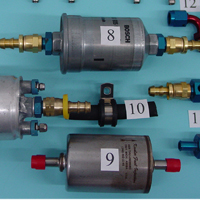

Figure

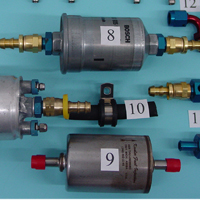

10 From this outlet

to the fuel rail use -6 (3/8”) hose. Alcohol

fueled

motors need larger, but that is a whole other

story.

Figure

10 From this outlet

to the fuel rail use -6 (3/8”) hose. Alcohol

fueled

motors need larger, but that is a whole other

story.

Figures

8 & 9 Inline filters protect the fuel injectors.

They are 8 micron rated and available with both fittings and barbs. You need

a filter with no less than 5/16” inside openings.

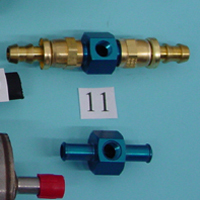

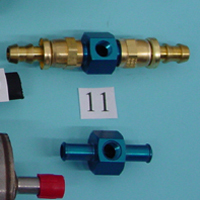

Figure 11 Fittings

with fuel pressure (1/8” pipe) ports are available for use with both

fittings and barbs. We also have pressure port fittings that thread

directly into the filter outlet. These are pictured elsewhere on

our website.

Figure

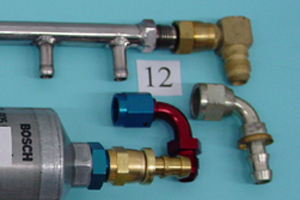

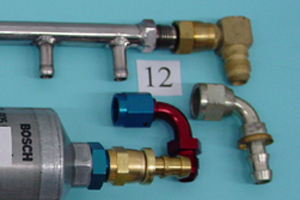

12 shows a few samples of -6 elbows

that attach to the 2.5 fuel rail inlet. The tube 90 degree hose

ends are a nice touch, but honestly, their importance is hard to

determine at this connection. Remember that the welded male flare

that comes on the Mercury 2.5 fuel rail is called -6 J.I.C.. Dash

6 fittings (and -12) come in two sizes; J.I.C. and S.A.E. You need

J.I.C. for this.

Figure

12 shows a few samples of -6 elbows

that attach to the 2.5 fuel rail inlet. The tube 90 degree hose

ends are a nice touch, but honestly, their importance is hard to

determine at this connection. Remember that the welded male flare

that comes on the Mercury 2.5 fuel rail is called -6 J.I.C.. Dash

6 fittings (and -12) come in two sizes; J.I.C. and S.A.E. You need

J.I.C. for this.

Fuel Rail Assembly

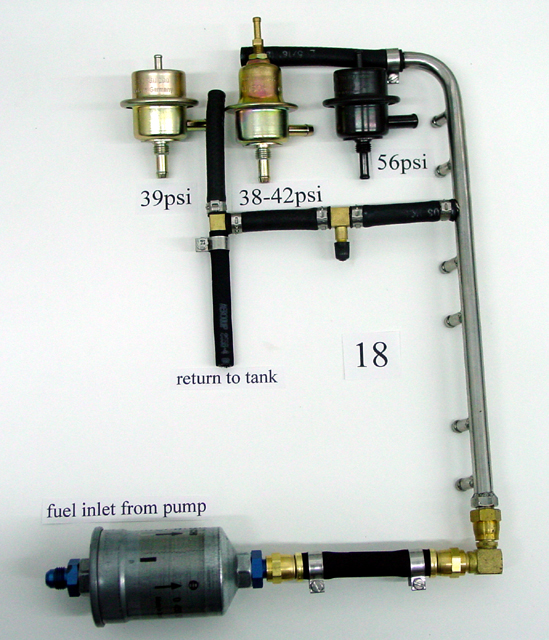

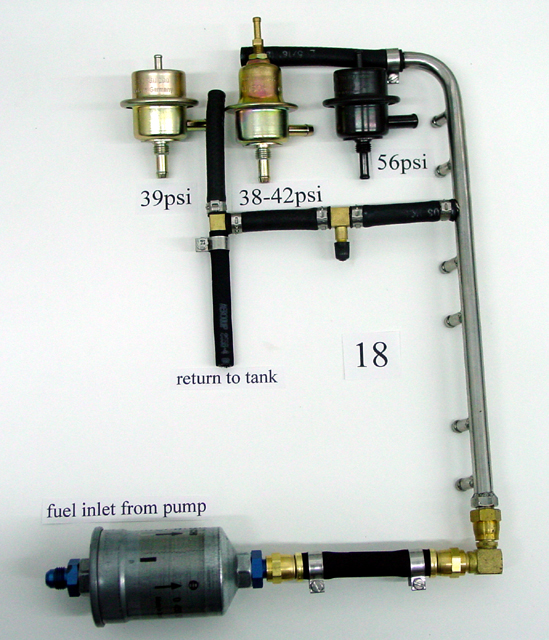

Figure 18 We

should mention a few things regarding the return from the regulator.

Ideally, it needs to be back into the main tank far away from the

pick-up. The Pro Max (“Laser”) style system came to be because the Coast

Guard cringes at the thought of a fuel line returning to the boat.

Finding an empty port in the main tank is the first choice. If

there is no fitting available, fabricate an aluminum (Stainless,

brass, bronze) splice to install into the fuel fill hose with an

angled fitting or barb to accept the return line. Once in the main

tank, the return fuel can cool and dissipate any air bubbles that

may have formed. If a line directly to the main tank is impractical,

it is okay to plumb the return fuel into an empty “in” port

on your water separator housing. This method has inadvertently

saved many people from problems. In the late eighties, we would

weld a fitting to the side of the Kinsler filter on the suction

side of the Weldon pump. This was a quick cure to remove the bog

from hard turning tunnel boats. Theoretically not the best method

but it worked. If you use a catch tank system, then use the port

you hopefully welded on top.

This photo shows pumps that are more necessary

for the competing outboard drag racer. Large

volume pumps seem to be necessary to maintain stable pressure on

the race track. These large pumps satisfy the needs of large 4 stroke

engines and yet we still need them on our little two strokes. Here

we can skip the theories and go with what works. Typically

a small fuel cell is used with fittings located in a small sump at

the rear bottom. A single -10 fitting must be installed, however

most cells come with two -8 fittings. Run the two -8 lines to a “Y” block

with a -10 outlet and you will be just fine.

Figure

14 Aftermarket inline filters are available from a few sources.

Be sure they have -10 connections. Figure 13 this is the Weldon pump

which Mercury has supplied on and off since the 2.4 Bridgeport era.

These are noisy, expensive, battery killers, but otherwise fabulous

pumps. When purchased from Mercury Racing, they include the Kinsler

filter so Figure 14 will not be used.

Figure

14 Aftermarket inline filters are available from a few sources.

Be sure they have -10 connections. Figure 13 this is the Weldon pump

which Mercury has supplied on and off since the 2.4 Bridgeport era.

These are noisy, expensive, battery killers, but otherwise fabulous

pumps. When purchased from Mercury Racing, they include the Kinsler

filter so Figure 14 will not be used.

Figure 15 is a -10 hose sample with a stainless

steel Adel clamp. Drag racers can also

use the two -8 fittings in their fuel cells to feed two Bosch pumps in parallel

into a “Y” block having a -6 outlet. We had our customers use this

method back in the early-mid nineties. Some still use it today. If

your stand pipe style tank has a bung for a return line, you can install a

second stand pipe in that return line port. (you must find a new place for

the return hose) Bend this new pick up towards the front of the tank to help

solve slosh problems that can arise from larger un-baffled tanks. Join the

two stand pipes to a “Y” block and then complete the system.

also

use the two -8 fittings in their fuel cells to feed two Bosch pumps in parallel

into a “Y” block having a -6 outlet. We had our customers use this

method back in the early-mid nineties. Some still use it today. If

your stand pipe style tank has a bung for a return line, you can install a

second stand pipe in that return line port. (you must find a new place for

the return hose) Bend this new pick up towards the front of the tank to help

solve slosh problems that can arise from larger un-baffled tanks. Join the

two stand pipes to a “Y” block and then complete the system.

Figure

16 is our Bosch Magnum pump. It uses

a -10 inlet with a built-in 20 micron screen. This pump fits the

traditional mount, but we always end up fabricating custom ones.

Soon we will have a “standard” custom mount for sale.

Figure 10 once again is a sample of -6 outlet hose.

Figure

8,9,11 are filters and fittings.

The final topic that we have not yet covered are boats that require “Catch

Tank Systems". This is where a low pressure

transfer pump fills a small vented tank (vent line feeds back to the main fuel

tank) from which the high pressure pump can draw the fuel. Big hulls, high

speeds, tight turns, and high seas all require this simple but necessary system.

Hard turning smaller tunnel boats can use this system as well, but a set-up

with just one pump often is preferred. These small single tank boats easily

can use custom tanks that feature baffles, sumps and one way trap doors to

accomplish anti-sloshing.

A common inexpensive transfer pump

is the “Red” Holley.

Do not waste your money on the “Blue” model as it is the same pump

with a different bypass spring. The “Blue” pump comes with a regulator

needed for carburetors. You will not use it so why pay for it? On vessels running

in salt water it is necessary to paint these pumps and mounts because they

tend to get ugly fast.

The pick-up side of a catch tank system is more forgiving than the other

type because the low pressure pump does the work from the main tank. "Hard"

90 degree fittings are prevalent in larger boat’s stand pipes due to

clearance issues (decks and bulkheads) and boat builder unawareness.

The fuel is then

pumped to the catch tank where hopefully the air bubbles will be dissipated.

The catch tank supplies the high pressure pump with a consistent and unrestricted

fuel supply and sends it on to the fuel injectors.

In closing, we cannot stress the importance of free flow to the inlet side

of the EFI pumps in all applications. Tees and 90 degree fittings are commonly

used by people because they lay out nicely on a bulkhead and because they are

space savers. “Hard “90

degree fittings are a commonplace at the inlet side of water separators to

avoid “unsightly” loops in the hose. Here is an old rule of thumb

to keep in mind. A “hard” 90 degree fitting on the suction side

is like adding 15’ of length to your hose. Give your current lay out

a closer look; you may be shocked to see how restrictive it is.

Hopefully, the outboard hot rodder can benefit from these simple guidelines.

The properly rigged boat will give you safety, reliability, and top performance.

See

you at the races,

Joe and Marty Signorelli

.

Figure

1 shows one simple way

of making a stand pipe for your existing tank. We use ½” o.d.

soft copper tubing (the kind that is sold in coils). Tanks usually

have a 3/8” pipe female threaded bung or bushing on the top,

so simply machine a brass 3/8” pipe male to -8 adapter so that

the straightened ½” o.d. copper tube slides inside.

Solder them together with silver solder (lead solder works fine as

well) and you are now well on your way to success.

Figure

1 shows one simple way

of making a stand pipe for your existing tank. We use ½” o.d.

soft copper tubing (the kind that is sold in coils). Tanks usually

have a 3/8” pipe female threaded bung or bushing on the top,

so simply machine a brass 3/8” pipe male to -8 adapter so that

the straightened ½” o.d. copper tube slides inside.

Solder them together with silver solder (lead solder works fine as

well) and you are now well on your way to success. Figure

2 are examples of what you do not

want. These are however widely used and tolerable in another system’s design that

use transfer pumps to fill a “catch” tank. We will

discuss this later in the article.

Figure

2 are examples of what you do not

want. These are however widely used and tolerable in another system’s design that

use transfer pumps to fill a “catch” tank. We will

discuss this later in the article. Figure

3 Top off the new -8 adapter with a TUBE 90 degree elbow. Do

not use any more 90 degree fittings en route to the high pressure pump

inlet (suction side of system).

Figure

3 Top off the new -8 adapter with a TUBE 90 degree elbow. Do

not use any more 90 degree fittings en route to the high pressure pump

inlet (suction side of system). available

in a variety of metals and platings. Tube 90 degree elbows made in brass unfortunately,

do not seem to be available.

available

in a variety of metals and platings. Tube 90 degree elbows made in brass unfortunately,

do not seem to be available. Figure

19 demonstrates electrolysis formed under the hose end

at the stainless steel braid. This hose assembly was removed

from the bilge of an outboard offshore race boat that was craned

out every afternoon. It never sat overnight in a marina. Stainless

steel and aluminum together may be the the best recipe for

electrolysis. Stainless braided hoses are risky in another

respect. In a thrash a steel fuel hose assembly accidentally

draped across a battery will no doubt spoil the weekend. Some

shops use plastic coated braided -4 trim hoses for this reason.

(they do turn ugly amber color however).

Figure

19 demonstrates electrolysis formed under the hose end

at the stainless steel braid. This hose assembly was removed

from the bilge of an outboard offshore race boat that was craned

out every afternoon. It never sat overnight in a marina. Stainless

steel and aluminum together may be the the best recipe for

electrolysis. Stainless braided hoses are risky in another

respect. In a thrash a steel fuel hose assembly accidentally

draped across a battery will no doubt spoil the weekend. Some

shops use plastic coated braided -4 trim hoses for this reason.

(they do turn ugly amber color however).

Figure

10 From this outlet

to the fuel rail use -6 (3/8”) hose. Alcohol

fueled

motors need larger, but that is a whole other

story.

Figure

10 From this outlet

to the fuel rail use -6 (3/8”) hose. Alcohol

fueled

motors need larger, but that is a whole other

story.

Figure

12 shows a few samples of -6 elbows

that attach to the 2.5 fuel rail inlet. The tube 90 degree hose

ends are a nice touch, but honestly, their importance is hard to

determine at this connection. Remember that the welded male flare

that comes on the Mercury 2.5 fuel rail is called -6 J.I.C.. Dash

6 fittings (and -12) come in two sizes; J.I.C. and S.A.E. You need

J.I.C. for this.

Figure

12 shows a few samples of -6 elbows

that attach to the 2.5 fuel rail inlet. The tube 90 degree hose

ends are a nice touch, but honestly, their importance is hard to

determine at this connection. Remember that the welded male flare

that comes on the Mercury 2.5 fuel rail is called -6 J.I.C.. Dash

6 fittings (and -12) come in two sizes; J.I.C. and S.A.E. You need

J.I.C. for this.

Figure

14 Aftermarket inline filters are available from a few sources.

Be sure they have -10 connections. Figure 13 this is the Weldon pump

which Mercury has supplied on and off since the 2.4 Bridgeport era.

These are noisy, expensive, battery killers, but otherwise fabulous

pumps. When purchased from Mercury Racing, they include the Kinsler

filter so Figure 14 will not be used.

Figure

14 Aftermarket inline filters are available from a few sources.

Be sure they have -10 connections. Figure 13 this is the Weldon pump

which Mercury has supplied on and off since the 2.4 Bridgeport era.

These are noisy, expensive, battery killers, but otherwise fabulous

pumps. When purchased from Mercury Racing, they include the Kinsler

filter so Figure 14 will not be used.  also

use the two -8 fittings in their fuel cells to feed two Bosch pumps in parallel

into a “Y” block having a -6 outlet. We had our customers use this

method back in the early-mid nineties. Some still use it today. If

your stand pipe style tank has a bung for a return line, you can install a

second stand pipe in that return line port. (you must find a new place for

the return hose) Bend this new pick up towards the front of the tank to help

solve slosh problems that can arise from larger un-baffled tanks. Join the

two stand pipes to a “Y” block and then complete the system.

also

use the two -8 fittings in their fuel cells to feed two Bosch pumps in parallel

into a “Y” block having a -6 outlet. We had our customers use this

method back in the early-mid nineties. Some still use it today. If

your stand pipe style tank has a bung for a return line, you can install a

second stand pipe in that return line port. (you must find a new place for

the return hose) Bend this new pick up towards the front of the tank to help

solve slosh problems that can arise from larger un-baffled tanks. Join the

two stand pipes to a “Y” block and then complete the system.